The Role of Aluminum Foil Fiberglass Sleeves in Extreme Environments: A Deep Dive into Protective Principles

Exploring the Mechanisms of Radiant Heat Barrier

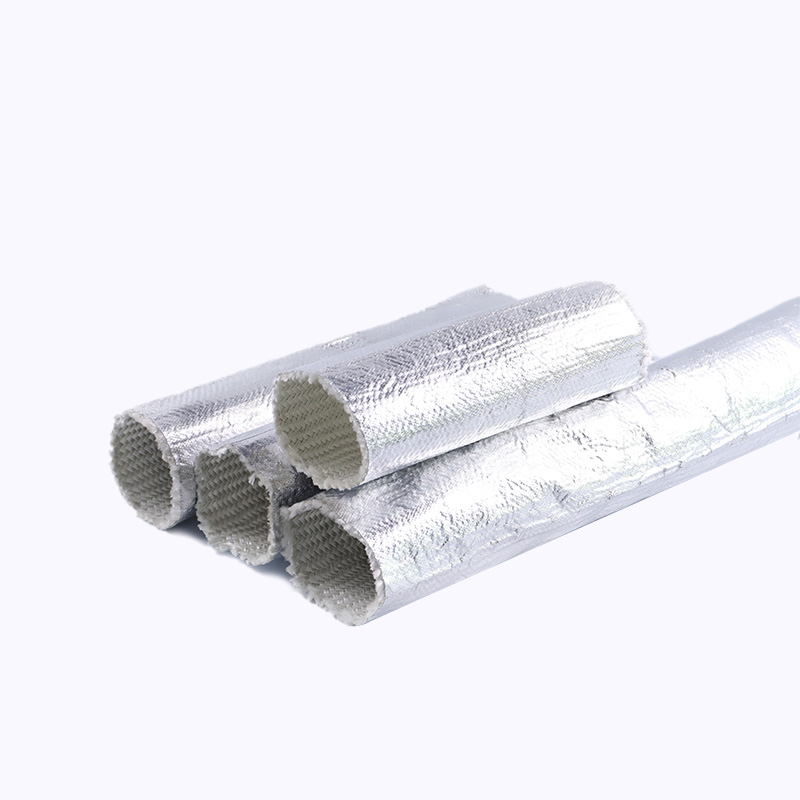

The fundamental protective capability of the aluminum foil fiberglass sleeve is rooted in its highly polished outer layer of aluminum. This reflective surface is not merely aesthetic; it is a meticulously engineered component designed to combat the pervasive threat of radiant heat. Radiant energy, such as the intense thermal output from exhaust manifolds or industrial furnaces, travels as electromagnetic waves. When these waves strike the aluminum surface, the material's low emissivity allows it to reflect a substantial percentage of this heat away—often exceeding 95%—before it can be absorbed by the underlying fiberglass layer or, more importantly, the critical components housed within the sleeve. This deflection of energy is crucial, creating an effective thermal barrier and minimizing the heat load imposed on sensitive wires, cables, and hoses, which are otherwise vulnerable to rapid degradation and failure under extreme thermal stress.

Material Synergy: The Combined Advantages of Aluminum and Fiberglass

The genuine strength of this protective solution lies in the synergistic combination of its two primary materials. The exterior aluminum foil serves as the primary defense against radiant heat, but the inner core of braided or woven fiberglass provides essential secondary and structural benefits. Fiberglass is inherently an excellent thermal insulator, possessing a high continuous working temperature and a low thermal conductivity. Any small fraction of radiant heat that manages to penetrate the aluminum layer, along with convective heat from the surrounding air, is then significantly slowed down and absorbed by the fiberglass base fabric. Moreover, the fiberglass provides exceptional mechanical resilience, offering abrasion resistance and structural integrity that a thin aluminum film alone could not achieve. This duality of high reflectivity from the aluminum and superior insulation and durability from the fiberglass ensures comprehensive, multi-layered protection against both thermal and physical threats in harsh operating conditions.

In-Depth Analysis of Practical Application Scenarios

Protecting Wiring and Hoses in Automotive High-Temperature Zones

In the modern automotive industry, particularly within the densely packed engine bay of high-performance vehicles, trucks, and heavy equipment, localized high-temperature zones pose a constant risk to electrical systems and fluid transfer lines. The aluminum fiberglass sleeve is widely employed to safeguard wiring harnesses, fuel lines, hydraulic hoses, and sensor cables that must run in close proximity to engine exhaust components or turbochargers. The material’s flexibility allows it to conform to complex routing paths, which is an enormous advantage in constrained spaces. The longevity of a vehicle’s operational safety is heavily dependent on the integrity of these protected lines. For a successful automotive heat reflective sleeve installation guide, technicians must ensure the sleeve extends beyond the actual heat source, providing an adequate buffer zone, and should be secured properly to prevent sliding or contact with sharp edges, ensuring the reflective layer remains intact for maximum efficiency.

Thermal Management for Critical Components in Industrial and Aerospace Settings

Beyond automotive use, these sleeves are critical in industrial manufacturing, metal processing, and aerospace applications where heat generation is immense and inescapable. Conveyor systems near molten materials, complex fluid transfer systems in foundries, and the engine compartments of aircraft rely on the best applications for aluminum fiberglass heat shield technology to prevent catastrophic failures. The material's capacity to withstand high intermittent temperatures makes it a reliable shield for instrumentation and control cables that monitor and regulate extreme processes. In aerospace, where component weight and performance are equally vital, the relatively lightweight and highly effective heat reflection of the sleeve makes it an optimal choice for maintaining stable operating temperatures for essential electronic and pneumatic lines.

Technical Specifications and Selection Guidance

Distinguishing the Performance of Thermal Protection Sleeves

When specifying protective sleeving for high-temperature applications, it is paramount to understand the difference between aluminized fiberglass sleeve and fire sleeve. While both offer thermal protection, they serve distinct purposes. The aluminized fiberglass sleeve excels as a radiant heat reflector and an insulating barrier against heat exposure, leveraging the aluminum for deflection. In contrast, traditional fire sleeves are typically thick, silicone-coated fiberglass braids designed primarily as a robust shield against direct flame and molten splash, often for a defined, limited duration. The primary strength of the aluminized variety is continuous heat reflection and insulation, whereas a true fire sleeve is an ultimate, albeit often bulkier, defense against direct flame impingement, leading to different weight, flexibility, and installation considerations for engineers.

Key Factors in How to Select High-Temperature Wire Protection Sleeves

Effective selection of a protective sleeve hinges on a careful assessment of the operating environment. Engineers must first determine the maximum continuous and intermittent temperatures the sleeve will be exposed to. Furthermore, the selection process needs to account for the nature of the heat—is it predominantly radiant, convective, or conductive? The sleeve's internal diameter and necessary length must accommodate the components being protected, allowing for minor thermal expansion. Crucially, the operating environment demands consideration of additional threats, such as chemical exposure, fluid splashes, or intense abrasion. The material must be rated to resist these factors, ensuring the integrity of both the reflective outer layer and the underlying insulation.

The Long-Term Benefits of Thermal Insulation

Boosting System Efficiency Through Heat Reflection

One of the often-overlooked advantages of using this highly reflective sleeving is the subtle yet significant increase in system efficiency. By reflecting radiant heat away from the surrounding environment and the protected components, the sleeve minimizes heat absorption by nearby structures and the equipment itself. This reduction in ambient heat load can lead to lower energy expenditure for cooling systems, especially in enclosures or cabinets where temperature control is critical. These benefits of aluminum foil over fiberglass insulation alone—the ability to actively reflect heat rather than merely passively insulate—contribute to a cooler, more stable operating platform for all components within the immediate vicinity.

Extending Component Lifespan and Reducing Maintenance Costs

The primary economic justification for installing high-quality thermal sleeving is the demonstrable effect it has on component longevity. Exposure to high heat is a leading cause of failure for electrical insulation, plastic components, and rubber hoses, which can become brittle, crack, or melt. By maintaining a stable, lower internal temperature for these critical components, the aluminum foil fiberglass sleeve significantly reduces the rate of thermal degradation. This proactive protection translates directly into fewer unexpected equipment failures, reduced downtime for repairs, and a substantial decrease in the long-term maintenance costs associated with frequently replacing heat-damaged parts. It is an investment in operational reliability and sustained performance.

Summary of Key Protective Features

- Reflection of radiant heat (up to 95%).

- Insulation from convective and conductive heat.

- Protection against abrasion and mechanical damage.

- Chemical and fluid resistance.