In demanding industrial, automotive, and aerospace environments, protecting critical components from extreme heat is not an option—it's a necessity. A high temperature resistant sleeve serves as a first line of defense, a passive yet vital component engineered to insulate, shield, and extend the service life of wires, hoses, pipes, and sensitive equipment. These sleeves are not simple covers; they are specialized products designed from advanced materials to withstand continuous exposure to radiant and convective heat, direct flame, abrasion, and chemical splash. Selecting the correct sleeve is a technical decision that directly impacts system safety, reliability, and operational cost. This guide provides an in-depth exploration of sleeve types, from common silicone high temperature resistant sleeve options to specialized fiberglass high temperature sleeve for wires, their core functions, and the critical factors involved in specification, including when to consider a custom sized high temperature resistant sleeve for unique applications.

Core Functions and Material Science

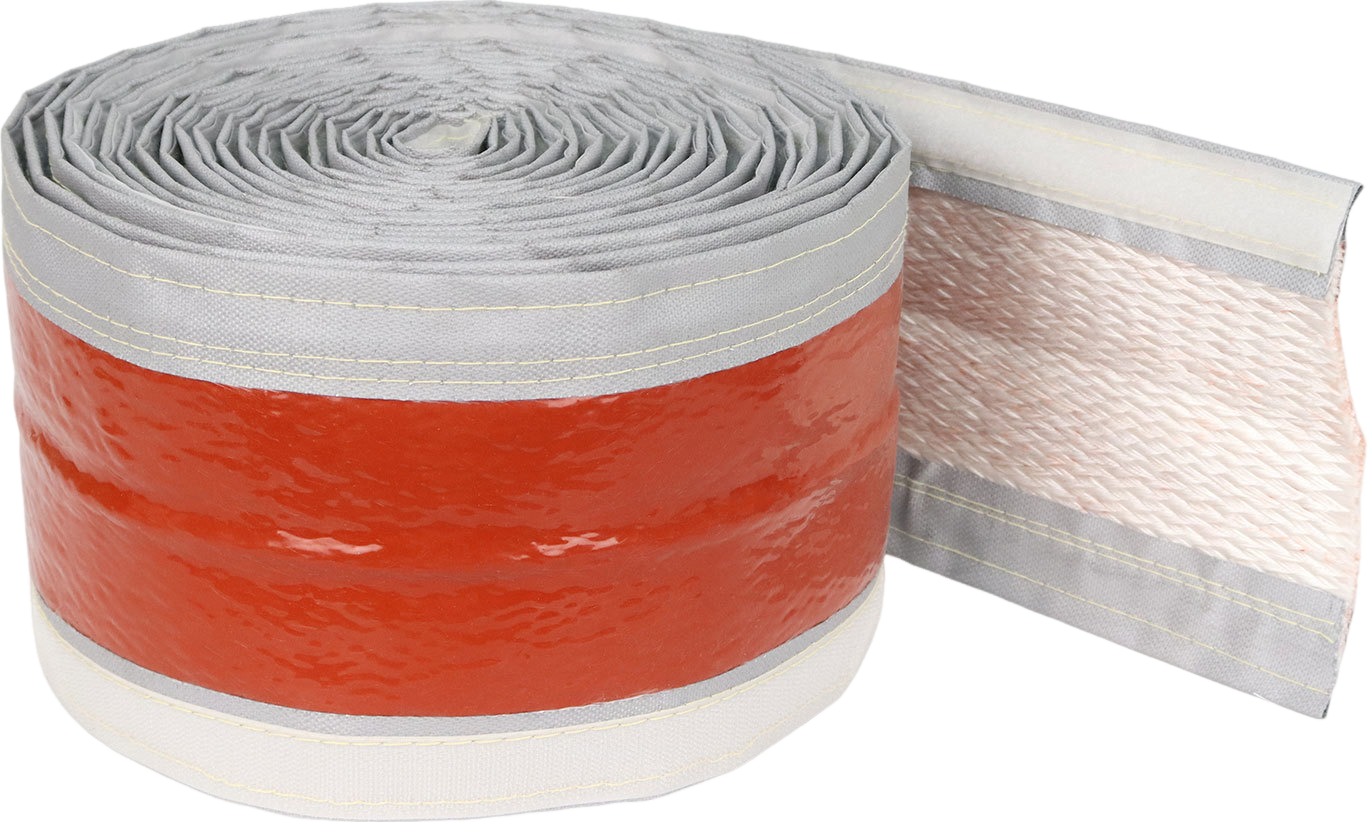

The fundamental purpose of a high-temperature sleeve is to manage thermal energy and provide physical protection in hostile environments. Its roles are multifaceted. Primarily, it acts as a thermal barrier, significantly reducing heat transfer to the component inside, whether that's preventing hydraulic fluid from overheating, stopping wire insulation from degrading, or protecting nearby sensitive parts from radiated exhaust heat. Beyond insulation, these sleeves offer essential mechanical protection against abrasion from vibration, accidental impact, and cutting from sharp edges. Many are also engineered to be highly flame-retardant or self-extinguishing, meeting stringent safety standards to prevent the spread of fire in case of a leak or electrical fault. The ability to perform these functions reliably hinges on the material science behind them. Different polymers and inorganic fibers offer distinct performance envelopes. For instance, a silicone high temperature resistant sleeve provides exceptional flexibility and good resistance up to approximately 260°C (500°F), making it ideal for dynamic applications with constant movement. In contrast, a fiberglass high temperature sleeve for wires, woven from inorganic silica strands, can withstand continuous temperatures exceeding 540°C (1000°F) and offers excellent dielectric properties, making it perfect for protecting wiring looms in engine bays or near industrial furnaces.

- Thermal Insulation: Creates a barrier against radiant and convective heat to protect internal components and maintain their performance.

- Abrasion & Mechanical Protection: Shields against wear from vibration, chafing, and impact, prolonging the life of hoses and cables.

- Flame Retardancy: Many sleeves are designed to resist ignition and prevent flame propagation, a critical safety feature.

- Chemical & Fluid Resistance: Protects against oils, fuels, coolants, and solvents that could degrade the component.

Industry-Specific Applications and Product Types

The application dictates the sleeve's required form and material. In electrical systems, protecting wiring harnesses is paramount. Sleeves used here, such as the aforementioned fiberglass high temperature sleeve for wires, are often braided for flexibility and ease of installation over complex wire runs. They prevent insulation meltdown and short circuits. In fluid power systems, the challenge shifts to protecting hydraulic and pneumatic hoses from external heat sources that can degrade the hose material and weaken the fluid. A braided high temp sleeve for hydraulic hoses is specifically designed for this, often using a high-strength, temperature-resistant weave to guard against both heat and physical abrasion from nearby machinery. One of the most severe applications is in the automotive and motorsports industry for exhaust management. An automotive exhaust high temperature sleeve must handle direct contact with exhaust manifolds and pipes, where surface temperatures can exceed 700°C (1300°F). These sleeves are frequently constructed from multiple layers—such as an inner glass fiber core for insulation wrapped in a durable, heat-reflective stainless steel or aluminized outer braid—to manage extreme temperatures, reduce under-hood heat soak, and protect mechanics from burns.

| Application Area | Primary Threat | Recommended Sleeve Type | Key Benefit |

| Wiring Harnesses (Engine Bay, Industrial Panels) | Radiant heat, abrasion, occasional fluid splash. | Fiberglass Braided Sleeve, Silicone Coated Fiberglass. | Prevents insulation degradation and electrical failure, maintains signal integrity. |

| Hydraulic/Pneumatic Hoses (Manufacturing, Mobile Equipment) | External heat sources, abrasive wear from contact. | Heavy-Duty Braided Sleeve (Fiberglass, Aramid). | Protects hose integrity, prevents fluid overheating, extends hose life. |

| Exhaust Components (Automotive, Marine, Power Generation) | Extreme radiant and convective heat (500°C+). | Multi-Layer Insulating Sleeve (e.g., Fiberglass + Aluminized Outer). | Lowers surface temperatures, contains heat, protects adjacent components, improves safety. |

| Sensitive Components & Sensors | Localized high-temperature exposure. | Silicone high temperature resistant sleeve or Precision-Engineered Wrap. | Flexible protection for irregular shapes, good thermal and chemical resistance. |

Critical Selection Guide and Specification

Choosing the correct high-temperature sleeve requires a systematic analysis of the operating environment and performance needs. The most critical parameter is the temperature range, which includes both the continuous operating temperature and any short-term peak exposures the sleeve must survive. Other vital specifications include abrasion resistance (often tested via Taber or Martindale tests), chemical compatibility with present fluids, flexibility/bend radius, and required safety certifications (e.g., UL, MIL-spec, SAE). Often, standard sleeve sizes and materials are sufficient. However, unique challenges such as unusually large or small diameters, non-circular cross-sections, or the need for integrated mounting points necessitate a custom sized high temperature resistant sleeve. The customization process involves collaboration with an engineering manufacturer to select the optimal base material, weave pattern, and diameter, and may include creating specific tooling for braiding or coating to achieve the exact dimensions and performance characteristics required for the application, ensuring a perfect fit and maximum protection.

- Temperature Rating: Always select a sleeve whose continuous and peak temperature ratings exceed the worst-case scenario in your application.

- Chemical Compatibility: Verify that the sleeve material is resistant to any oils, fuels, solvents, or other chemicals it will encounter.

- Diameter and Fit: A proper fit is crucial; too tight restricts installation and may compress insulation, too loose reduces protection and can catch on objects.

- Certifications: For regulated industries (automotive, aerospace, marine), ensure the product meets the necessary industry or military standards.

- Installation Environment: Consider factors like required flexibility, UV exposure (for outdoor use), and the need for easy removal for maintenance.

Material Comparison and Decision Matrix

With several high-performance materials available, selecting the right one is foundational. The choice typically balances temperature capability, flexibility, durability, and cost. Silicone rubber offers the best combination of flexibility and mid-range heat resistance, along with good chemical resistance. Fiberglass provides the highest heat resistance and excellent insulation but can be less flexible and abrasive to nearby surfaces if not coated. Aramid fibers (like para-aramid) offer exceptional strength and abrasion resistance with good high-temperature performance. The following table provides a clear comparison to guide the initial selection process.

| Material | Max Continuous Temp. (Approx.) | Key Strengths | Considerations | Typical Use Case |

| Silicone Rubber | 200°C - 260°C (392°F - 500°F) | Extremely flexible, good chemical resistance, wide range of colors. | Lower max temperature than inorganic options. Can be punctured. | General wire bundling, protection of low-temp hoses, areas requiring high flexibility. |

| Fiberglass (Uncoated) | 540°C+ (1000°F+) | Extremely high temp resistance, excellent electrical insulator, inorganic (won't burn). | Can be brittle; may irritate skin during handling; requires careful cutting. | Exhaust wraps, furnace area wiring, high-temp pipe insulation. |

| Fiberglass (Silicone Coated) | 260°C - 480°C (500°F - 900°F) | High temp resistance, improved abrasion resistance, sealed against moisture and contaminants. | Slightly less flexible than pure silicone; coating can degrade at highest temps. | Protected wiring harnesses, hydraulic hose sleeving in hot environments. |

| Aramid (Para-Aramid) | 200°C - 250°C (392°F - 482°F) | Outstanding tensile strength and cut/abrasion resistance, flame resistant. | Higher cost; can degrade under UV light if uncoated. | Heavy abrasion zones, protection for critical hoses and cables in racing or aerospace. |

FAQ

1. What's the difference between a silicone sleeve and a fiberglass sleeve? When should I use each?

The core difference lies in temperature resistance and flexibility. A silicone high temperature resistant sleeve is best for applications requiring constant flexing, bending, or vibration in environments up to about 260°C. It's also easier to handle and install over connectors. A fiberglass high temperature sleeve for wires is your choice for static or semi-static applications where temperatures exceed 260°C, such as near exhaust manifolds, turbochargers, or industrial ovens. Fiberglass is inorganic and will not burn, offering superior ultimate heat protection but with less inherent flexibility.

2. How do I measure for and choose the right size sleeve for my hose or wire bundle?

Accurate measurement is critical. For a hose or pipe, measure the outer diameter (OD). For a wire bundle, gather all wires together as they will be routed and measure the bundle's circumference; divide this by 3.14 (π) to estimate the effective diameter. The sleeve's inner diameter (ID) should be 25-50% larger than the component's OD to allow for easy installation and a slight air gap that aids insulation. If standard sizes don't fit your component—especially common with large hydraulic assemblies or odd-shaped bundles—a custom sized high temperature resistant sleeve is the solution to ensure optimal performance and protection.

3. Can I use a high-temperature sleeve on my car's exhaust?

Yes, using an automotive exhaust high temperature sleeve is a common and effective practice. It is specifically designed to handle direct contact with extremely hot exhaust components. These sleeves lower the external surface temperature, which reduces under-hood heat soak (improving performance and component life), protects nearby wiring and hoses, and provides a safety barrier against accidental contact burns. Ensure you select a sleeve rated for continuous exposure to temperatures higher than your exhaust system's measured surface temperature.

4. Are these sleeves only for heat, or do they offer other protection?

While heat resistance is the primary feature, high-quality sleeves offer multi-functional protection. They provide significant abrasion resistance, shielding components from wear caused by vibration against chassis parts or other components. Many also offer protection from fluids like oil, fuel, and coolant, and can contain minor leaks or sprays. The braided structure of a braided high temp sleeve for hydraulic hoses, for example, is excellent at defending against both external heat and physical abrasion from nearby machinery.

5. What does "continuous temperature rating" mean, and is it safe to exceed it briefly?

The continuous temperature rating is the maximum temperature at which the sleeve can operate indefinitely while maintaining its structural integrity and protective properties. Most sleeves also have a higher "peak" or "intermittent" temperature rating, which is a temperature they can withstand for a short, defined period (e.g., 15-30 minutes). It is crucial to select based on the continuous rating for your normal operating conditions. While brief excursions to the peak rating may be survivable, consistently exceeding the continuous rating will cause the material to degrade rapidly—through hardening, cracking, or melting—and fail to provide protection.