In the complex landscape of electrical engineering and industrial maintenance, the protection of wiring and hoses is not merely a matter of organization but a critical safety requirement. Selecting the appropriate heat resistant electrical sleeve is a fundamental decision that dictates the longevity of electrical systems and the prevention of catastrophic failures. As industrial machinery becomes more compact and automotive engine bays run hotter, the thermal stress on wiring harnesses increases exponentially. A high-quality sleeve acts as a thermal barrier, protecting sensitive cables from ambient heat, direct flame exposure, and abrasive wear. Furthermore, these sleeves provide essential dielectric insulation, preventing short circuits and ensuring operator safety. The choice of sleeving involves a careful analysis of material composition, thermal ratings, environmental exposure, and mechanical flexibility. For procurement managers and engineers, understanding these nuances is key to optimizing supply chain efficiency and ensuring compliance with rigorous international safety standards.

Ningguo Zhongdian Insulation Materials Co., Ltd. is a technology-driven enterprise specializing in the design, research and development, production, and sales of high-temperature resistant and fireproof new materials. Located in the Yinbai Industrial Park of Ningguo City, Southeast Anhui, within a national-level economic development zone, the company has been a leader in the field since its establishment in 2008. Holding import and export rights and boasting certifications such as ISO9001 Quality Management System and ISO14001 Environmental Management System, Ningguo Zhongdian ensures top-tier quality control. Their high-temperature-resistant composites sleeves are known for flame retardancy and strong tensile strength, serving industries including metallurgy, mining, shipbuilding, chemicals, and automotive. With successful EU CE certification, US UL flame retardant certification, and ROHS6 testing, their subsidiary brands "Zhongdian New Materials" and "CEIP" are recognized globally, providing reliable heat resistant electrical sleeve solutions to markets in the United States, Southeast Asia, and beyond.

Material Composition: Fiberglass vs. Silicone

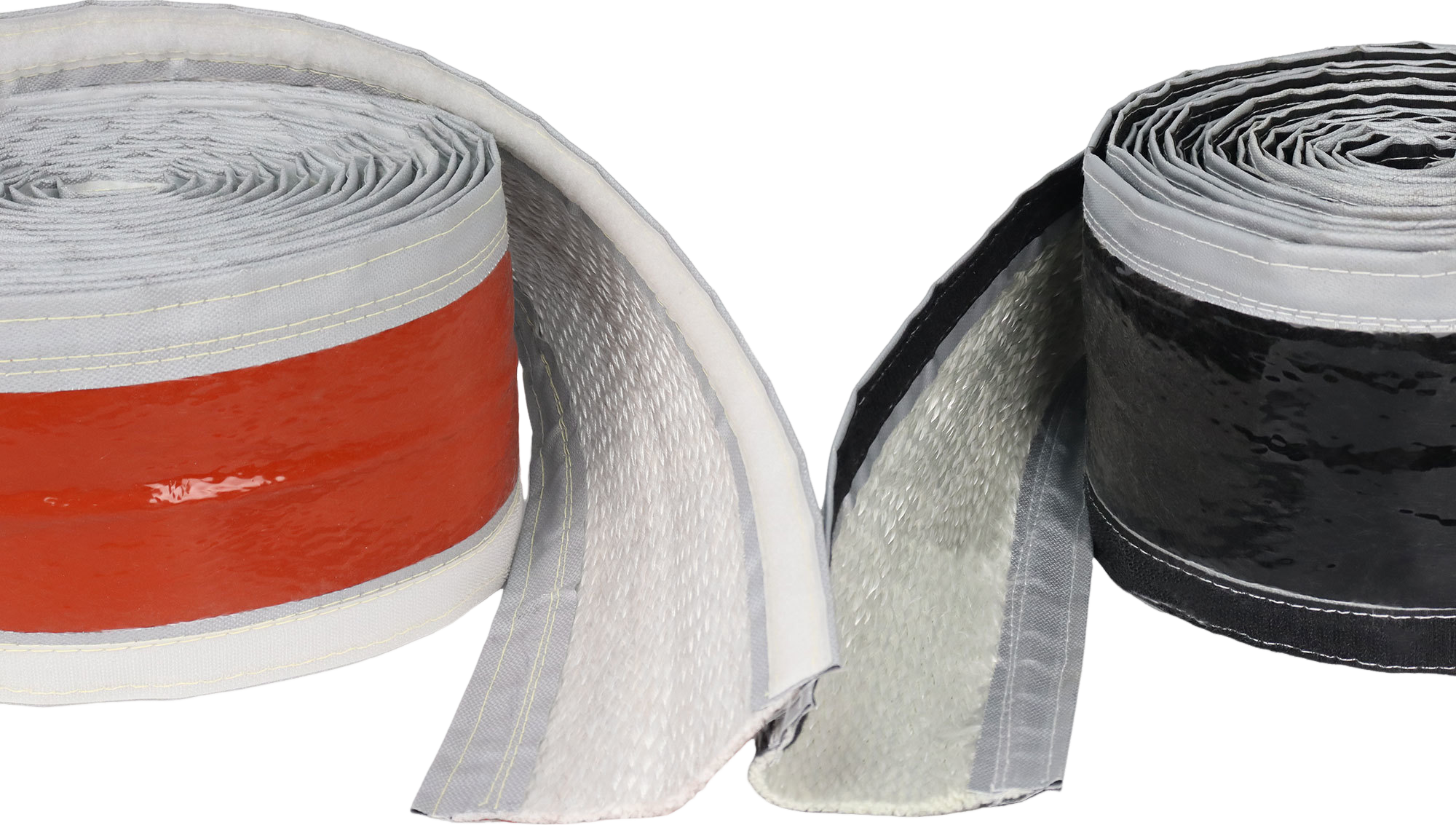

The material composition of a protective sleeve is the primary determinant of its thermal performance and durability. The market is dominated by two primary categories: bare or coated fiberglass sleeves and those utilizing advanced silicone rubber compounds. Fiberglass serves as an excellent base material due to its inherent inorganic nature, which means it does not melt or drip when exposed to extreme heat. However, fiberglass alone can be abrasive to handle and may shed fibers. To mitigate this, manufacturers often apply a coating. Silicone rubber is the most common coating for high-end applications because of its exceptional thermal stability and flexibility. Silicone can withstand continuous exposure to high temperatures while remaining pliable, a crucial feature for installations that require the sleeve to bend around tight corners. The synergy between the high tensile strength of fiberglass and the thermal protection of silicone creates a composite material ideally suited for harsh environments.

- Thermal Stability: Materials must maintain structural integrity without degrading under continuous heat exposure.

- Dielectric Strength: High insulation resistance to prevent leakage currents in high-voltage applications.

- Abrasion Resistance: The outer coating must protect the inner fiberglass from wear and fraying.

- Chemical Resistance: Ability to resist oils, solvents, and hydraulic fluids common in industrial settings.

- Flexibility: The sleeve must remain pliable to allow for easy installation over complex wire bundles.

The Role of High Temperature Fiberglass Sleeve

A high temperature fiberglass sleeve is often the first line of defense in heavy industrial applications where extreme heat is a constant factor. Constructed from braided E-glass or S-glass fibers, these sleeves are capable of withstanding temperatures ranging from 540°C to over 1000°C for short durations. The braiding structure allows the sleeve to expand slightly to accommodate fittings and connectors, providing a snug fit without requiring specialized tools for installation. In many scenarios, these sleeves are used as a base layer, providing the maximum thermal resistance, while a secondary outer layer might be added for specific chemical resistance or color-coding purposes. For applications like furnace wiring or exhaust system protection, the high temperature fiberglass sleeve is indispensable due to its non-combustible nature.

td>Very soft and flexible.td>Excellent insulator even at high temps. td>Variable; decreases as temperature rises.

| Feature | High Temperature Fiberglass Sleeve | Standard Textile Sleeve |

| Max Temperature Resistance | Up to 540°C continuous (1000°C intermittent). | Typically up to 150°C to 200°C. |

| Flammability | Non-combustible; does not support flame. | May melt or burn depending on synthetic content. |

| Flexibility | Flexible but can be itchy; often coated. | |

| Dielectric Strength |

Benefits of Silicone Rubber Electrical Insulation Sleeve

While fiberglass provides the heat resistance, the silicone rubber electrical insulation sleeve adds a layer of comprehensive protection that enhances safety and usability. The silicone rubber coating encapsulates the fiberglass braiding, sealing the fibers to prevent skin irritation and dust generation. This coating is highly resistant to oxidation, UV exposure, and ozone, making it suitable for outdoor applications as well as enclosed engine bays. Crucially, the silicone rubber provides a smooth surface that is easy to clean and offers excellent grip resistance, which is vital for preventing slippage in vibrating machinery. The silicone rubber electrical insulation sleeve is particularly favored in the automotive and aerospace industries because it meets strict flame retardancy standards, such as the UL VW-1 vertical burn test, ensuring that the sleeve self-extinguishes if it does catch fire.

td>-60°C to +260°C. td>-20°C to +105°C.td>May melt and drip; limited flame resistance.td>Excellent resistance to UV, ozone, and weathering. td>Prone to cracking and degradation under UV light.td>Good; silicone rubber acts as a sacrificial wear layer. td>Good initially but hardens with age.

| Performance Factor | Silicone Rubber Coated Sleeve | Vinyl Coated Sleeve |

| Temperature Range | ||

| Flame Retardancy | Self-extinguishing (UL VW-1 compliant). | |

| Environmental Resistance | ||

| Abrasion Resistance |

Application Scenarios: Automotive vs. Industrial

Determining the correct application environment is crucial when selecting a protective sleeve, as the demands of an automotive engine bay differ significantly from those of a factory floor. In automotive applications, the primary enemies are heat from the exhaust and combustion, along with constant vibration and exposure to road salts, oils, and fuels. Industrial applications may involve exposure to molten splash, high-voltage arcs, or chemical mists. Therefore, the sleeving must be chosen not just for its temperature rating, but for its chemical compatibility and mechanical resilience. Utilizing the wrong type of sleeve can lead to premature hardening, cracking, or even melting, which exposes the underlying wires to damage.

- Vibration Dampening: Sleeves must absorb constant movement without wearing through the wire insulation.

- Fluid Resistance: Resistance to brake fluid, transmission fluid, and engine oil is critical.

- Abrasion: Protection against chafing against metal frames or other sharp edges.

- Thermal Cycling: Ability to expand and contract with rapid temperature changes without cracking.

- Compression Set: The sleeve should not permanently deform under clamping pressure.

Protecting Critical Systems with Automotive Wire Protection Sleeve

In the automotive sector, the complexity of modern engines requires a sophisticated approach to wire management. An automotive wire protection sleeve is specifically engineered to handle the harsh under-hood environment. These sleeves often feature a high-grade silicone coating that meets specific automotive industry standards such as ISO 6722 and SAE J1673. The primary function is to prevent the insulation of the wiring harness from melting, which could cause electrical shorts leading to engine failure or fire. Additionally, the automotive wire protection sleeve helps organize the massive bundles of wiring found in modern vehicles, making assembly easier and providing a clean aesthetic finish. Manufacturers like Ningguo Zhongdian produce sleeves that are heat-shrinkable or braided with expandability up to 300%, facilitating installation over complex connectors.

td>-40°C to +260°C (peaks higher near exhaust).td>RoHS, ELV (End of Life Vehicles), AEC-Q. td>RoHS, REACH, ISO 9001.

| Environment | Automotive Application | General Industrial Application |

| Primary Hazard | Intermittent high heat, vibration, oil exposure. | Constant high heat, dust, molten splash, chemicals. |

| Temperature Range | Up to 540°C or higher depending on proximity to furnaces. | |

| Physical Stress | High vibration and flexing. | Tension, compression, and abrasion. |

| Compliance |

Installation Methods: Flexible vs. Shrinkable

The method of installation is a practical consideration that can significantly affect labor costs and installation time. There are two primary categories of sleeving: flexible braided sleeves and heat shrinkable sleeves. Flexible sleeves are typically braided and can stretch to allow them to be slipped over connectors and terminals before retracting to fit snugly. This makes them ideal for retrofits or field installations. Heat shrinkable sleeves, on the other hand, are manufactured in an expanded state. Once placed over the wire bundle, heat is applied, causing the sleeve to shrink tightly around the bundle, often providing a moisture-proof seal. The choice between these two depends on whether the priority is speed of installation or the need for a completely hermetic seal.

- Expandability Ratio: How much the diameter can expand to accommodate connectors.

- Shrink Ratio: The degree to which heat shrink tubing contracts (typically 2:1 or 3:1).

- Tooling Requirements: Whether a heat gun or oven is required for installation.

- Reusability: Flexible sleeves can often be removed; heat shrink sleeves usually must be cut off.

- Wall Thickness: Shrink sleeves often provide a thicker, more rigid wall after shrinking.

Versatility of Flexible Heat Shrink Tubing Sleeve

The flexible heat shrink tubing sleeve offers a unique advantage by combining the ease of installation of heat shrink materials with the mechanical protection of a sleeve. These products are often constructed with a polyolefin or silicone wall that shrinks dramatically when heated, conforming perfectly to the shape of the wire bundle. This creates a barrier that is impervious to water, dust, and fuels, which is excellent for splices or terminations exposed to the elements. Unlike rigid braided sleeves, a flexible heat shrink tubing sleeve provides a finished look that is resistant to snagging. For B2B buyers, these sleeves are often specified in repair kits or for applications where a high degree of environmental sealing is necessary alongside thermal protection.

td>Hermetic seal; waterproof and dustproof.td>Difficult to remove without cutting. td>Can often be removed and reused if not secured with ties.

| Installation Characteristic | Flexible Heat Shrink Tubing Sleeve | Braided Fiberglass Sleeve |

| Seal Quality | Porous; allows airflow and moisture permeation unless coated. | |

| Installation Speed | Slower; requires heat source (heat gun/oven). | Fast; simply slide over and cut to length. |

| Wall Thickness | Thicker and rigid after shrinking. | Thin and flexible; maintains wire bundle flexibility. |

| Removability |

Standards and Certifications

When sourcing heat resistant electrical sleeve, verifying compliance with industry standards is non-negotiable for ensuring liability protection and safety. Certifications such as UL (Underwriters Laboratories), CE (Conformite Europeenne), and RoHS (Restriction of Hazardous Substances) serve as benchmarks for product quality. The UL certification, particularly the flame retardant ratings, is critical for products used in North America, ensuring that the sleeve will not propagate a fire. RoHS compliance ensures that the product is free from hazardous substances like lead and mercury, which is a legal requirement in the EU and increasingly elsewhere. Ningguo Zhongdian Insulation Materials Co., Ltd. exemplifies this commitment by holding ISO9001, ISO14001, CE, UL, and ROHS6 certifications, ensuring that their heat resistant electrical sleeve products meet the rigorous demands of global markets.

- UL Flame Rating: Indicates the material's resistance to ignition and self-extinguishing properties.

- ISO 9001: Certifies that the manufacturer follows consistent quality management processes.

- RoHS/REACH: Ensures the product is environmentally safe and free from restricted substances.

- ASTM Standards: May apply to the physical properties like tensile strength and abrasion resistance.

- Traceability: Ability to trace the batch and raw materials of the sleeve for warranty claims.

FAQ

What is the maximum temperature a fiberglass electrical sleeve can withstand?

The maximum temperature depends on the specific grade of fiberglass and whether it is coated. A standard high temperature fiberglass sleeve can typically withstand continuous temperatures of up to 540°C (1000°F) and short-term exposure up to 1090°C (2000°F) without melting. If the sleeve is coated with silicone rubber, the maximum continuous temperature is usually limited to around 260°C (500°F), as that is the melting point of the silicone coating. For applications exceeding this, an uncoated or vermiculite-coated fiberglass version is recommended.

Are heat resistant sleeves waterproof?

Not inherently. Standard braided heat resistant electrical sleeve, even if silicone coated, is water-resistant but not fully waterproof, as the braid structure can allow moisture to penetrate under pressure. To achieve a waterproof seal, a flexible heat shrink tubing sleeve is required. These sleeves shrink tightly around the cable bundle, creating a barrier that prevents water ingress, making them ideal for outdoor connections or marine applications where water exposure is a concern.

Can I use a heat resistant sleeve for hydraulic hoses?

Yes, heat resistant electrical sleeve is frequently used to protect hydraulic hoses in industrial and mobile equipment. These sleeves protect the hose from external heat sources, such as engine manifolds or exhaust systems, which could cause the hydraulic fluid to overheat or the hose rubber to degrade. Additionally, they provide a barrier against accidental sprays of hot oil or sparks. The automotive wire protection sleeve is also highly effective in this role due to its resistance to oils and fuels.

What is the difference between "expandable" and "heat shrink" sleeves?

The primary difference lies in the installation method and the final fit. Expandable sleeves are braided and can be stretched over connectors easily, then they relax to form a snug but flexible fit; they are excellent for applications where the wires may need to move or flex. Flexible heat shrink tubing sleeve, on the other hand, is manufactured larger than its final size and requires a heat source to shrink down onto the wire bundle. This provides a much tighter, rigid, and sealed fit that offers better protection against environmental ingress and abrasion.

Why is silicone coating important on fiberglass sleeves?

The silicone coating on a silicone rubber electrical insulation sleeve serves several critical functions. First, it binds the fiberglass fibers together, preventing the "itchy" shedding of glass fibers that can cause skin irritation and contaminate machinery. Second, it significantly improves the abrasion resistance of the sleeve, acting as a tough outer skin. Third, it adds a layer of dielectric insulation and environmental protection against ozone, UV, and water. Without the coating, the fiberglass is purely a heat shield but offers little protection against oil or physical wear.