With the continuous upgrading of modern industry and increasingly stringent environmental protection requirements, the development of new materials has become an important driving force for the progress of the industry. Basalt Fabric, as an emerging mineral-based fiber material, is gradually entering the field of vision of multiple industrial fields due to its unique physical and chemical properties and environmentally friendly characteristics. This article will deeply analyze the basic characteristics, industrial applications and unique advantages of Basalt Fabric to help you better understand how this material promotes the green transformation and performance improvement of the industry.

1. Basic characteristics of Basalt Fabric

1.1 What is Basalt Fabric?

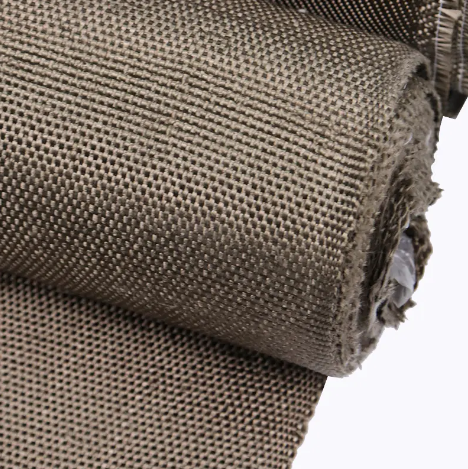

Basalt Fabric is an inorganic fiber fabric made of natural basalt ore through high-temperature melt drawing. Basalt is a rock formed by volcanic eruptions, rich in silicate minerals, and has excellent high temperature resistance and corrosion resistance. Through advanced melt spinning technology, basalt rock is converted into fine and uniform fibers, and then formed into cloth-like materials through a weaving process. This material is naturally inorganic, does not add harmful substances, and has excellent heat resistance and mechanical properties.

1.2 Physical and chemical properties

Basalt Fabric has the following remarkable physical and chemical properties:

High temperature tolerance: It can withstand temperatures up to 700°C or even higher, far exceeding general organic fiber materials, and is suitable for extreme high temperature environments.

Corrosion resistance: It has good resistance to various corrosive media such as acid, alkali, salt spray, etc., and prolongs its service life.

Mechanical strength and toughness: It has high tensile strength and good toughness, and can effectively resist mechanical impact and wear.

1.3 Environmental protection and sustainability characteristics

As a natural mineral fiber, the production process of Basalt Fabric is environmentally friendly and energy-saving, and no harmful chemical additives need to be added. Basalt ore resources are abundant and mining is relatively environmentally friendly. The product can be recycled and reused, which is conducive to promoting material recycling and green manufacturing. In addition, Basalt Fabric is naturally non-toxic, non-radioactive, safer and more environmentally friendly.

2.Main applications of Basalt Fabric in the industrial field

2.1 High-temperature insulation materials

High-temperature environments pose severe challenges to the safety of industrial equipment and personnel. Basalt Fabric is widely used in thermal insulation protection of power equipment such as transformers and boilers due to its excellent heat resistance. At the same time, it is used in the thermal protection layer of aircraft engines and rockets in the aerospace field to effectively reduce heat loss and improve operational safety and efficiency.

2.2 Fireproof and flame retardant materials

The demand for fire protection in construction and industrial production continues to increase. Basalt Fabric has natural flame retardancy, is not easy to burn, and does not release harmful gases when burning. It has become an ideal material for fireproof clothing, protective blankets and fireproof partitions, greatly improving the safety of personnel and equipment.

2.3 Reinforced fibers in composite materials

Lightweight and high strength are important directions for the manufacture of modern automobiles, ships, and railway vehicles. As a reinforcing fiber, Basalt Fabric can effectively improve the structural strength and durability of composite materials, replace traditional glass fiber or carbon fiber, reduce costs while improving performance, and help industrial product innovation and upgrading.

2.4 Anti-corrosion coating and protection

In industries such as chemical and petroleum, equipment is exposed to corrosive environments for a long time. Using Basalt Fabric as a coating substrate or protective layer can effectively isolate corrosive media, extend the service life of equipment, reduce maintenance costs, and ensure the continuity and safety of industrial production.

3. Analysis of the unique advantages of Basalt Fabric

3.1 High temperature performance is better than traditional fibers

Compared with glass fiber and carbon fiber, Basalt Fabric has a higher high temperature tolerance limit and maintains stable mechanical properties at high temperatures. This enables it to meet more demanding industrial thermal environment requirements and reduce the failure rate of equipment caused by high temperature.

3.2 Excellent mechanical strength and durability

Basalt Fabric has outstanding tensile strength and impact resistance. Even in complex industrial application environments, it can maintain a long service life and stable performance, greatly reducing replacement frequency and maintenance costs.

3.3 Excellent corrosion resistance and chemical resistance

Its natural resistance to a variety of corrosive media such as acids and alkalis makes Basalt Fabric the first choice for protective materials in harsh environments, greatly improving the protection effect and safety of industrial equipment.

3.4 Environmental advantages and sustainable development

Compared with traditional synthetic fibers, Basalt Fabric has natural sources, green production processes, and safe use, which helps promote industrial green transformation and conforms to the current global trend of energy conservation, emission reduction and sustainable development.

4. Technical challenges and development directions

4.1 Technical bottlenecks at this stage

Currently, the manufacturing cost of Basalt Fabric is relatively high, which limits its promotion in some fields. The processing technology is complex and has high requirements for equipment and technology, which also affects the efficiency of mass production.

4.2 Research hotspots and innovation directions

Future research focuses include improving the performance stability of fibers, developing multifunctional composite materials, and reducing manufacturing costs. New modification technologies and process innovations will further expand the application scope of Basalt Fabric.

4.3 Improvement of the industrial chain and market prospects

With the gradual improvement of the industrial chain and the growth of market demand, Basalt Fabric is expected to achieve large-scale application in more industrial fields and become an important part of green high-performance industrial materials.

5. Summary and Outlook

Basalt Fabric is becoming a new star in the field of industrial materials with its excellent high-temperature performance, mechanical strength and environmental protection characteristics. Facing the global wave of industrial green transformation, this natural mineral fiber fabric not only meets the stringent technical requirements, but also conforms to the concept of sustainable development. In the future, with the continuous breakthroughs in technology and the deepening of applications, Basalt Fabric will surely play an irreplaceable role in more industrial scenarios and lead a new wave of material innovation.